Elevate your metal casting process with our cutting-edge CERA-FUSION system

Featuring:

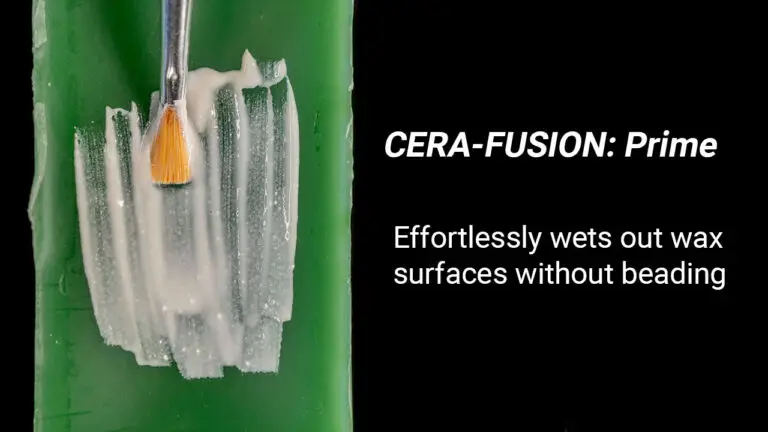

CERA-FUSION: PRIME

CERA-FUSION: ARMOR

This duo offers an unparalleled combination of ease of use and high-performance results in lost wax metal casting.

Easy to use:

- 1. Brush PRIME into high-detail areas

- 2. Dip for full coverage

- 3. Dust with pure silica sand

- 4. Allow to dry

- 5. Dip primed shell into ARMOR

- 6. Dust with pure silica sand

- 7. Allow to dry

- 8. Build up the shell by adding a total of 8 coats of ARMOR

Watch our 3-part video series below to learn more about:

- Wax Preparation

- Ceramic shell slurry application

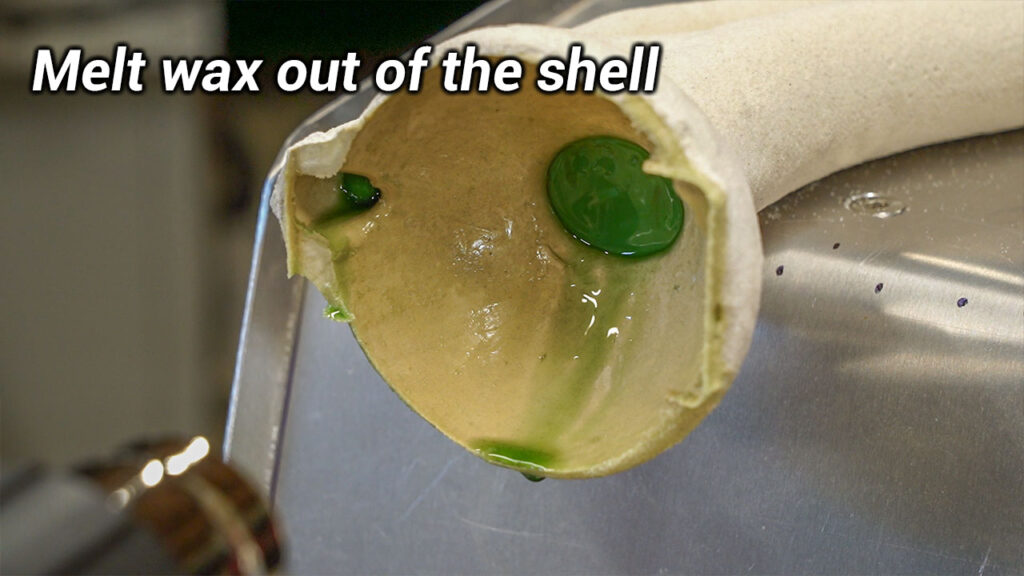

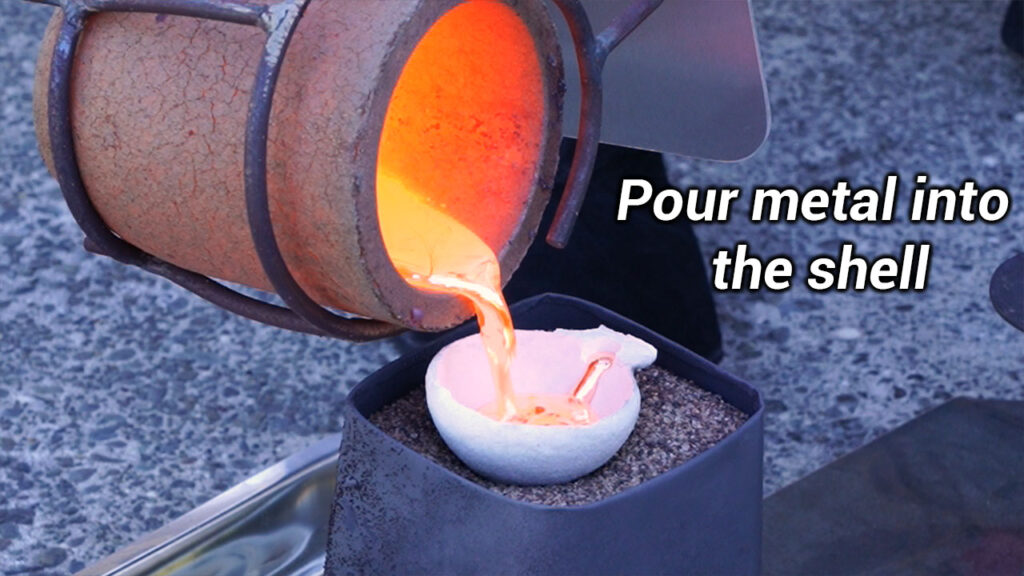

- Wax burnout and metal casting

DOWNLOAD/VIEW Cera-Fusion instructions: click here

PRIME is a foundation for success

- Superior Wet Out: effortlessly wets out wax surfaces without beading, ensuring high-detail capture in a single coat.

- High-Detail Capture: excels in capturing intricate details, setting the stage for the subsequent application of Cera-Fusion Fiber.

- Enhanced Thermal Conductivity: Experience quicker burnout, reduced risk of cracking, and faster drying between coats, thanks to the superior thermal transfer properties of both Prime and Fiber.

ARMOR builds a strong shell

Robust Shell Formation: Even before firing, the Cera-Fusion system provides a strong, durable hard shell, resistant to cracking and breakage during handling.

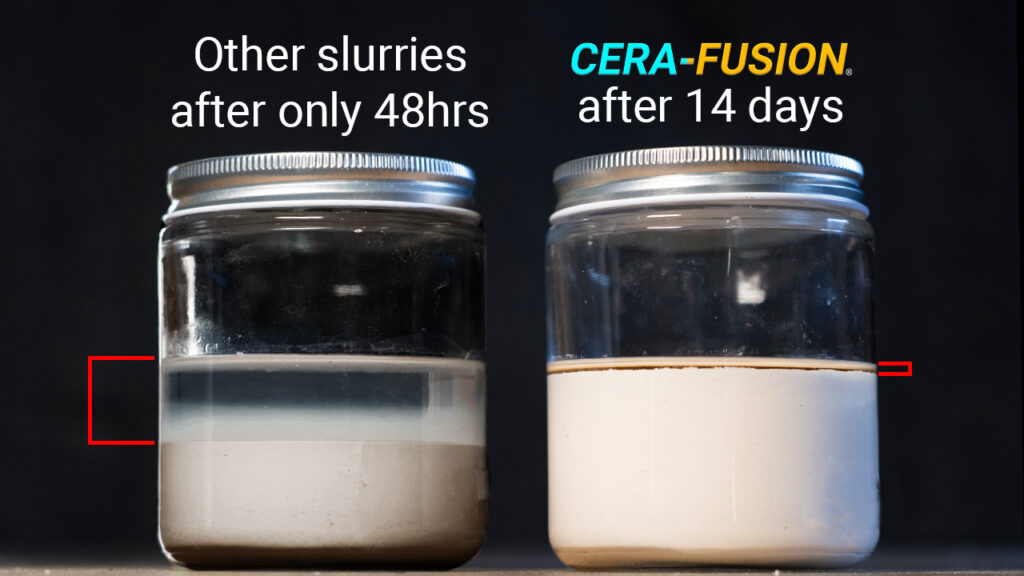

Excellent Slurry Suspension: Our eco-friendly and sustainable polymer formula ensures prolonged suspension without constant stirring.

Superior thermal conductivity: Compared to traditional silica ceramic slurries, Cera-Fusion has been formulated to conduct heat faster. This means the wax evacuates the shell quicker, and reduces the likelihood of thermal shock cracking the shell.

Excellent slurry suspension: CERA-FUSION has been formulated with a eco‐friendly and sustainable polymer. The components stay suspended for extended periods without the need for constant stirring during application to models or storage. We recommend to stir the slurry at least one a month to ensure quality is maintained.

Advantages of the

CERA-FUSION product system

- Delivered pre-mixed ready to use

- Superior Wet Out even on wax

- High Detail Capture

- Enhanced Thermal Conductivity

- Robust Shell pre and post-firing

- Quick Recoat Time

- User-Friendly Application and Maintenance

- Excellent Slurry Suspension

- Easy-to-Use Process

Download Safety Data Sheets:

Download Cera-Fusion instructions:

Buzzy Bee

A beloved Kiwi icon, the Buzzy Bee has been reimagined in silicone bronze, paua shell, and resin—preserving the nostalgia of childhood in lasting form.

The bronze components were cast using the Cera-Fusion product system, then carefully prepared, assembled, and finished. Texture, patina, and sealing bring out the character of the metal, adding depth and richness to its surface.

True to the original, this Buzzy Bee remains fully functional—its wheels spin, wings flutter, antennae bounce, and, most importantly, its signature clicker still sings.